At Plastic Molding Development, we recognize the environmental impact of plastic and understand the importance of environmental considerations in the plastic injection molding industry. As a specialized mold tryout shop with over 35 years of experience, we play a unique role in supporting our customers’ efforts to optimize their processes and potentially reduce environmental impact.

Our Role in the Industry

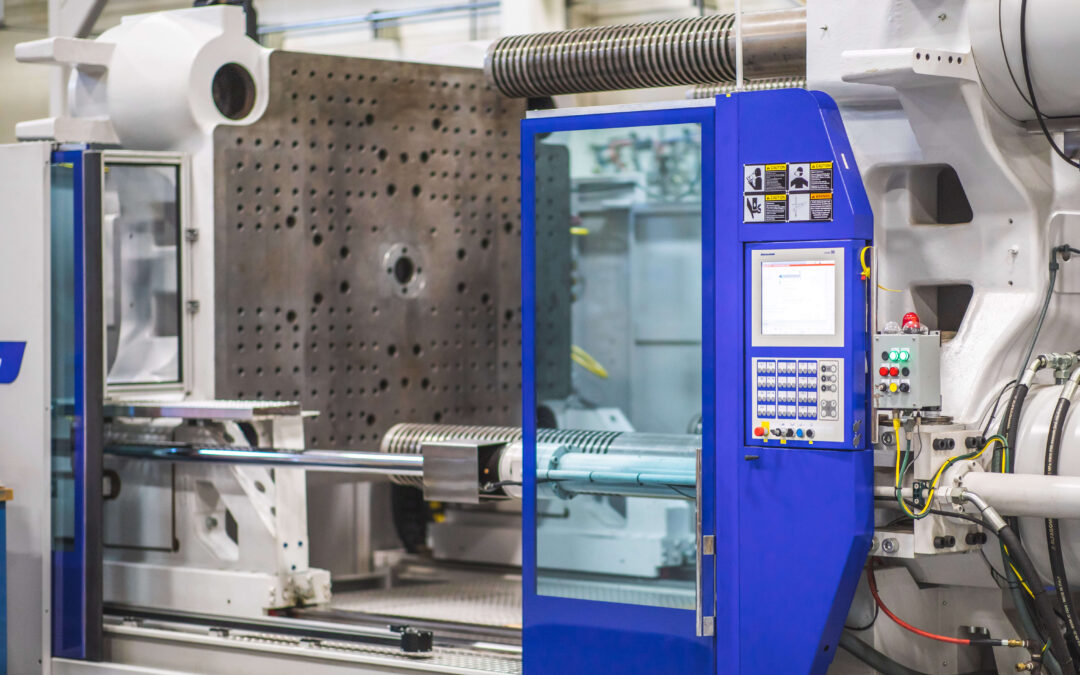

PMD provides crucial mold testing and tryout services, primarily to large automakers and other manufacturers. We offer a platform for our customers to test and refine their molds before full-scale production. While we don’t directly manufacture products or supply materials, our services can contribute to more efficient and potentially more environmentally conscious plastic production processes. We provide services pertaining to plastic injection molding, mold testing, aluminum and steel molds, short-run production, and more. But were more than just building quality short-run and mold tryouts, we build relationships. PMD does whatever it takes to deliver whatever you want, whenever you want it.

How Our Services Can Support Environmental Considerations

Our specialized services can indirectly support environmental initiatives through various means. We offer efficient mold testing, which helps identify and address potential issues before full-scale production, potentially reducing material waste. We also support material testing, allowing customers to experiment with different options, including potentially more eco-friendly alternatives, without disrupting their production lines.

Furthermore, our experienced process technicians assist in process optimization, identifying ways to improve mold performance and efficiency. These optimizations may lead to reduced energy consumption and material usage in the final production process. We also provide prototyping assistance, helping customers refine their designs before mass production, which can potentially lead to more efficient designs that use materials more effectively.

Environmental Initiatives and Applications

While PMD doesn’t directly control the materials or final products, our services can indirectly support our customers’ environmental initiatives. By helping customers optimize their molds and processes, we may contribute to reduced energy consumption and material waste in their final production. Our ability to test various materials allows customers to explore more sustainable options if they choose to do so. Through our tryout services, customers can refine their processes, potentially leading to more efficient production methods that could have a lower environmental impact.

It’s important to note that while we provide the testing platform and expertise, the choice of materials and final production decisions remain with our customers. We don’t supply materials (except for purging compounds to clean our machines), nor do we have engineering or research and development teams. Our role is to provide accurate and efficient mold tryout services that allow our customers to make informed decisions about their production processes. At Plastic Molding Development, we’re committed to providing high-quality mold tryout services that enable our customers to optimize their processes.

A Brighter, Better Future with PMD

At Plastic Molding Development, we’re committed to providing high-quality mold tryout services that enable our customers to optimize their processes. With over 35 years of experience, we are a customer-centric company that sets the stage for effective, efficient, and safe plastic injection mold testing. Our services can support our customers in their efforts to improve efficiency and potentially reduce environmental impact in their plastic injection molding processes.

We recognize that sustainability is an increasingly important consideration in the plastic molding industry. Through our mold tryout services, we aim to contribute to the industry’s progress by helping our customers refine their processes, which may lead to more efficient and potentially more environmentally conscious production methods. You can check out our latest blogs on our featured machines and plastic injection mold testing to learn more about our capabilities.

For more information about how our mold tryout services can assist in optimizing your plastic injection molding processes and potentially support your sustainability efforts, please contact us today. Together, we can work towards more efficient plastic molding practices that consider both production needs and environmental impact.